In the swiftly advancing globe of electronics, printed circuit card (PCBs) play an important role in making certain performance and integrity across a variety of gadgets. From microwave PCBs for communication systems to high-frequency PCBs in sophisticated applications, the demand for exact design and manufacturing processes has actually never ever been higher. Whether you're taking part in fast-turn custom PCB production or discovering the intricacies of high-density interconnect (HDI) PCBs, understanding the nuances of PCB assembly and style is crucial for achieving optimal efficiency in your electronic tools.

Custom PCB manufacturing is an essential aspect of modern electronics, enabling for customized options that fulfill details functional needs. Companies using these services accommodate a varied clients, from startups needing quick-turn prototypes to established enterprises getting started on comprehensive production runs. Fast turn printed circuit card assembly is particularly useful for markets that require speedy growth cycles, such as telecoms and consumer electronics. By leveraging advanced manufacturing technologies, consisting of micro vias and buried via methods, manufacturers can create intricate layouts that make best use of area and effectiveness within a minimal impact.

The demand for HDI PCBs has risen, driven by the enhancing functionality of devices loaded into smaller sized profiles. These boards make use of micro vias and advanced constructions to enable higher circuit density, crucial for contemporary applications in mobile phones, wearables, and IoT gadgets. Manufacturers like those concentrating on Megtron 6 and Megtron 7 products are at the center of this modern technology, offering products that supply remarkable electrical performance and thermal administration. The assimilation of these products into the manufacturing process of circuit card assemblies significantly improves item integrity and performance, making them indispensable in an extremely affordable landscape.

Flexible PCBs stand for another substantial innovation in innovation, allowing for bendable circuit styles that profit space-constrained applications. From flexible printed circuit board manufacturers to providers of RF PCBs, the market has experienced a shift toward extra adaptable remedies for modern electronics.

In the world of RF circuits, wireless communication innovations have actually fueled the need for specialized PCB designs, such as those utilizing Rogers materials. These products are crafted to preserve signal integrity at high regularities, making them the preferred option for applications calling for minimal loss and high-performance qualities. Companies that can give rapid prototyping and assembly for RF PCBs are distinctively placed to offer the needs of clients establishing sophisticated communication technologies.

The process of circuit board assembly involves various complex actions, consisting of the positioning of parts, soldering, and screening. Each stage plays a crucial role in ensuring that the final product meets quality standards and operational requirements. From low-volume PCB assembly for specialized applications to mass production of electronic circuit boards, the capability to control every aspect of the PCB manufacturing assembly process is important for companies seeking to improve their profits while maintaining high standards of quality.

Advancements in PCB fabrication methods, such as using blind and buried vias, have actually made it possible for developers to press the limitations of circuit density. Using these techniques not just improves electrical performance but also optimizes transmitting capacities, producing more small and elaborate designs. This performance is vital in today's electronics landscape, where space goes to a premium, and device capability continues to increase. Comprehending the dielectric residential or commercial properties of products such as FR-4 and other substances is important for designers aiming to make best click here use of performance.

For startups and well established companies alike, the value of custom PCB assembly can not be overemphasized. Whether it's creating a totally new line of items or repeating on existing designs, having access to efficient prototype PCB fabrication services can determine the speed of technology. By partnering with experienced PCB manufacturers who comprehend the nuances of PCB style and production, services can make certain a much shorter time-to-market, cost performance, and boosted item dependability. Quick-turn PCB boards improve this ability by enabling rapid versions based upon real-world screening and style recognition.

The versatility of PCBs extends throughout a multitude of applications, from commercial equipment to consumer electronics. Specialized circuit card styles accommodate unique applications, with each segment needing tailored remedies. In the automotive sector, high-frequency microwave circuits are significantly important as vehicles advance towards smarter technologies. Automotive manufacturers count on sophisticated circuit card assemblies to make certain the performance and reliability of necessary systems such as infotainment and safety and security features.

Respectable PCB manufacturing companies increasingly prioritize lasting practices in their operations. As ecological recognition grows, manufacturers are adopting greener techniques of PCB production and assembly, making use of lead-free solder and reducing waste during fabrication. Furthermore, the catalyst for better quality assurance procedures not just boosts customer safety but additionally bolsters conformity with global criteria, reassuring clients of their product's integrity.

Making use of flexible circuit card is reinventing numerous sectors as a result of their light-weight nature and capacity to suit varied kind variables. The growth of high-density interconnect PCBs has actually opened new avenues in fields such as telecommunications, where boosted information transfer capacities and reduced signal deterioration are important. As innovation advancements, the coexistence of rigid and flex PCBs makes it possible for developers to take advantage of the unique advantages of each while conference rigorous efficiency criteria.

Advancement in PCB prototyping services simplifies the trajectory from perception to produce. Companies seeking PCB prototype suppliers that integrate experience with cutting-edge modern technology can accomplish substantial advantages during the item growth phase. This fast-tracking of designs not just speeds up market entry yet also permits for higher innovative possibility as comments from prototype screening can drive subsequent design versions.

In the manufacturing landscape, using innovative software application for PCB layout and format makes sure precision in element placement and directing. Automation and AI-driven processes simplify assembly lines, making the production of detailed circuit assemblies much more reliable. Additionally, the increase of contract PCB assembly has actually allowed companies to concentrate on their core competencies while outsourcing intricate PCB production jobs to specialized partners who dramatically reduce above prices.

Finally, the birth of the digital age has ushered in an age where printed circuit card act as the backbone of contemporary electronics. The constant evolution of PCB innovation-- from high-frequency microwave applications to flexible board manufacturing-- highlights the vast potential for development within this field. Companies that comprehend the ins and outs of PCB fabrication, design, and assembly can leverage these developments to produce products that are not only high-performing but also reputable and affordable. As sectors significantly read more require much faster turn-around times and higher-quality requirements, the capability to offer services that cater to these demands will certainly specify the next generation of electronic devices and systems. With a focus on bespoke manufacturing procedures and ingenious materials, the future of printed circuit boards is positioned for amazing advancements, shaping the really material of innovation as we know it.

Christina Ricci Then & Now!

Christina Ricci Then & Now! Sam Woods Then & Now!

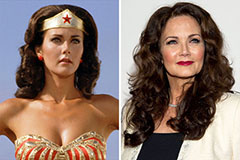

Sam Woods Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!